Photon Mission participates in the EU REPurpose project on safe and sustainable design of elastomeric plastics from recycling of post-consumer waste

Finding a sustainable way to shape a zero-waste economy is essential to keep the world’s consumption within its planetary boundaries, especially for versatile and widespread materials like plastics. The global consumption of materials such as biomass, fossil fuels, metals and minerals is expected to double in the next 40 years, with harmful consequences for humans and the environment. The annual plastics production is close to 380 Mt and is expected to double by 2035 and even quadruple by 2050, making it essential to find new solutions for effective and efficient use of resources for their production.

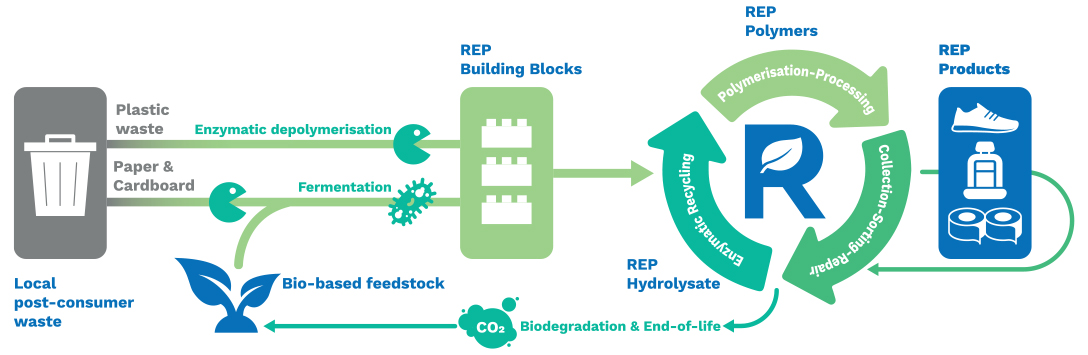

In this challenging scenario, the REPurpose project, funded by the European Union, brings together 10 partners from seven countries of the European Union and one associate partner from UK to be a game-changer in tackling recycling of polyethylene terephthalate (PET) and creating new thermoplastic elastomer polymers. REPurpose aims at developing and validating the production of a platform of Safe-and-Sustainable-by-Design, additive-free thermoplastic elastomer prototypes for speciality applications (consumer goods, automotive applications, building & construction) from local post-consumer waste, with intrinsic biodegradability and recyclability properties, and to establish the circular value chain in an enabling environment.

Work package 7

Photon Mission leads the WP7 on Circularity and end of life which includes testing, traceability, detection, QC & repolymerization. As a part of this work package Photon Mission is leading the efforts regarding traceability and detection. To do this we are evaluating several different photonics measurement techniques.

Hop on Facility program

The project also includes a Hop On Facility program to contribute to the ambition of inclusiveness of the future European Research Area by involving legal entities from low R&I performing countries to participate in already selected collaborative projects.

The REPurpose project had its official start on September 19th and 20th 2022 in Ghent, hosted by the Bio Base Europe Pilot Plant as coordinator of the research. Four universities and research centres, two non-profit organizations, and five SMEs will work together on these research challenges and lead the way to bring innovation to the general public and create a resilient and sustainable European plastics industry. This project has a total investment of 6.5 million euros.

Our goals and objectives

In the REPurpose project, local post-consumer waste is upcycled into new functional Recyclable Elastomeric Polymers (REP) destined for the high-value market of thermoplastic elastomers that today face recycling problems. New building blocks derived from biomass or enzymatically degraded organic or plastic waste will be incorporated, giving REP polymers unique characteristics:

-

-

- tunable elastomeric properties avoiding the need for additives

- production, processing and recycling on existing equipment

- controllable degradation in different habitats

- unprecedented indefinite recycling, surpassing fossil carbon at each recycling stage

-

How will we reach the goals?

New building blocks derived from biomass or enzymatically degraded plastic waste or paper and cardboard waste will be incorporated, giving the polymers unique characteristics of recyclability, ecology, and unlimited recycling, surpassing fossil carbon at each recycling stage. The polymers will be tested by relevant stakeholders and dedicated user groups, including global consumer goods producers.

Our strategy

- SSbD – Analyse and align relevant framework conditions for developing new REP polymers via an SSbD approach, targeting the just transition mechanism through a three-pillar approach of REP polymer life cycle sustainability.

- Production of Paper & Cardboard waste- and lignin-based monomers – Develop and scale processes to provide samples of renewable monomers from paper- and cardboard waste sugars and/or lignin-based aromatics for polymerisation.

- Plastizyme engineering, production and application – Develop, optimise and produce «plastizyme» enzymes that effectively degrade plastic waste into building blocks to be repolymerised into REP polymers. Later apply such plastizymes for REP recycling.

- REP polymer development and analysis – Build unique backbones by combining building block fractions from post-consumer waste leading to unique thermoplastic and elastomeric functional properties.

- REP product development and prototyping – Validate the potential of (post-)processing REP polymers through different industrial processes. Identify appropriate market applications matching the polymers’ functional behaviour..

- REP circularity and End of Life – Demonstrate the infinite recyclability and end-of-life solutions of the REP polymers by developing suitable detection, sorting, recycling and upcycling techniques.

- Exploitation, communication and dissemination – Demonstrate the expected impact of REP in terms of strengthening market opportunities and manufacturing capacities in the EU in short to medium term.

REPurpose beneficiaries are:

- Bio Base Europe Pilot Plant VZW (BE), Coordinator

- B4Plastics (BE)

- AIMPLAS – Plastics Technology Centre (ES)

- Renasci (BE)

- Italbiotec (IT)

- Saarland University (DE)

- Photon Mission (BE)

- University of Natural Resources and Life Sciences- BOKU (AT)

- University of Aalborg (DK)

- AVEP- Asociacion Valenciana De Empresarios De Plasticos (ES)

REPurpose Associate Partner is:

- Mellizyme Biotechnology Limited (now Epoch BioDesign, UK)

The REPurpose Project has received funding from the European Union under Grant Agreement No:101057971.

![]()

#EU #repurpose #sustainable #photon_mission