Dry Laser Cleaning

Dry laser cleaning semiconductor is a precise and contact-free method for removing contaminants such as grease, dust, or polymer residues without damaging the underlying material. It offers a clean, non-abrasive alternative to traditional chemical or mechanical processes. Femtum’s solution is based on worlds first and only 2.8 µm pulsed mid-infrared fiber laser, optimized for selective cleaning of semiconductor and optical components. The system combines high precision with easy integration into automated manufacturing environments.

Batch Spray & Wet Etch

Shellback Batch Spray & Wet Etch portfolio - Reduce chemical usage & address climate initiatives with TORRENT Eco-Clean. Since 2012 the award winning ozone cleaning solution has set the standard for chemical reduction, dramatically lowering your environmental impact while providing superior advanced cleaning. The extensive wet clean & etch portfolio also includes our 2023 acquisition of MERCURY+, an industry favorite for Low CoO, high throughput applications. TORRENT automated & semi-automated batch spray product line is the next evolution of our proprietary SEMITOOL technology up to 300mm for advanced clean, etch & strip.

SRD – Spin Rinse Dry

SHELLBACK next-gen SEMITOOL Spin Rinse Dryer with advanced controls that enhance ease-of-use, improves monitoring and management capabilities, and reduces operating costs.

The most effective, industry leading SRD system in the market. An evolution from SEMITOOL IP designed for ease of use and maximum performance. The best SRD just got better.

Industry leading SEMITOOL SRD800 Spin Rinse Dryer (SRD). Batch Spray System upto 300MM. Complete chemical and residue cleaning optimized for low particles and protection of substrates with innovative low cost of ownership.

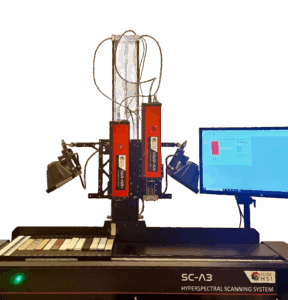

Hyperspectral Semiconductor Analysis

Our Hyperspectral Semiconductor Analysis solution combines hyperspectral imaging (HSI) with line-scan spectral ellipsometry to deliver powerful, non-destructive inspection capabilities for semiconductor wafers and thin films. This dual-technique platform enables both macro- and microscopic analysis for defect detection and material characterization.

This platform is ideal for semiconductor manufacturers aiming to improve yield, optimize thin-film processes, and enhance material quality control at every step.

Quantum Dot‑Powered SWIR Imaging

Our Quantum Dot–Powered SWIR Imaging system leverages state‑of‑the‑art colloidal quantum dot (QDot) sensors to unlock short‑wave infrared (900–1700 nm+) capabilities at a fraction of the cost of traditional InGaAs cameras. Designed for seamless integration into semiconductor fabs, this compact solution provides true sub‑surface visualization, essential for inspecting backside wafers, 3D IC bonds, micro‑cracks, and embedded particles.