Plastic pollution in one form or another can be found virtually everywhere on our planet. From cigarette butts, plastic bags and water bottles to microplastics, plastic is polluting our habitats, rivers, forests, beaches and oceans. Our tremendous attraction to plastic, coupled with its properties such as durability and resistance to corrosion and our single-use throw-away culture, have caused plastics to become ubiquitous. All of this creates a severe challenge for nature, society and the global economy.

To combat this crisis, we need to find eco-friendly alternatives to plastics, improve manufacturing processes, re-use and recycle plastic more efficiently and stop littering. Fortunately, technology can help us. Many sorting and recycling technologies are based on optical spectroscopy. NIR (Near infra-red) technology is an especially good tool for distinguishing different plastics from each other easily and improving the efficiency of sorting and recycling dramatically.

What are plastics?

Plastics were introduced to the world in the late 1940’s and early 50’s. Plastics became popular fast. They are versatile, lightweight, flexible, moisture resistant and strong. Unfortunately, they are also a menace to the environment, as these kinds of synthetic or semi-synthetic materials are made first and foremost from fossil fuels: crude oil, gas and coal. Its many variations such as ABS, Polycarbonate, Polyethylene, PET, PVC, Polypropylene and Polystyrene, are used in a huge and growing range of applications.

Plastics often contain additives that make them stronger, more flexible and durable. These properties can be modified with the addition of reinforcing fillers, colours, foaming agents, flame retardants, plasticisers, etc. Thanks to these additives, plastics are incredibly long-lasting.

Many of the additives used in plastics may contain chemicals such as phthalates, Bisphenol A (BPA) or flame retardants, many of which have been found harmful. They act as carcinogenic and endocrine disruptive chemicals, impairing neurological and immune systems in both humans and animals.

Scalable recycling

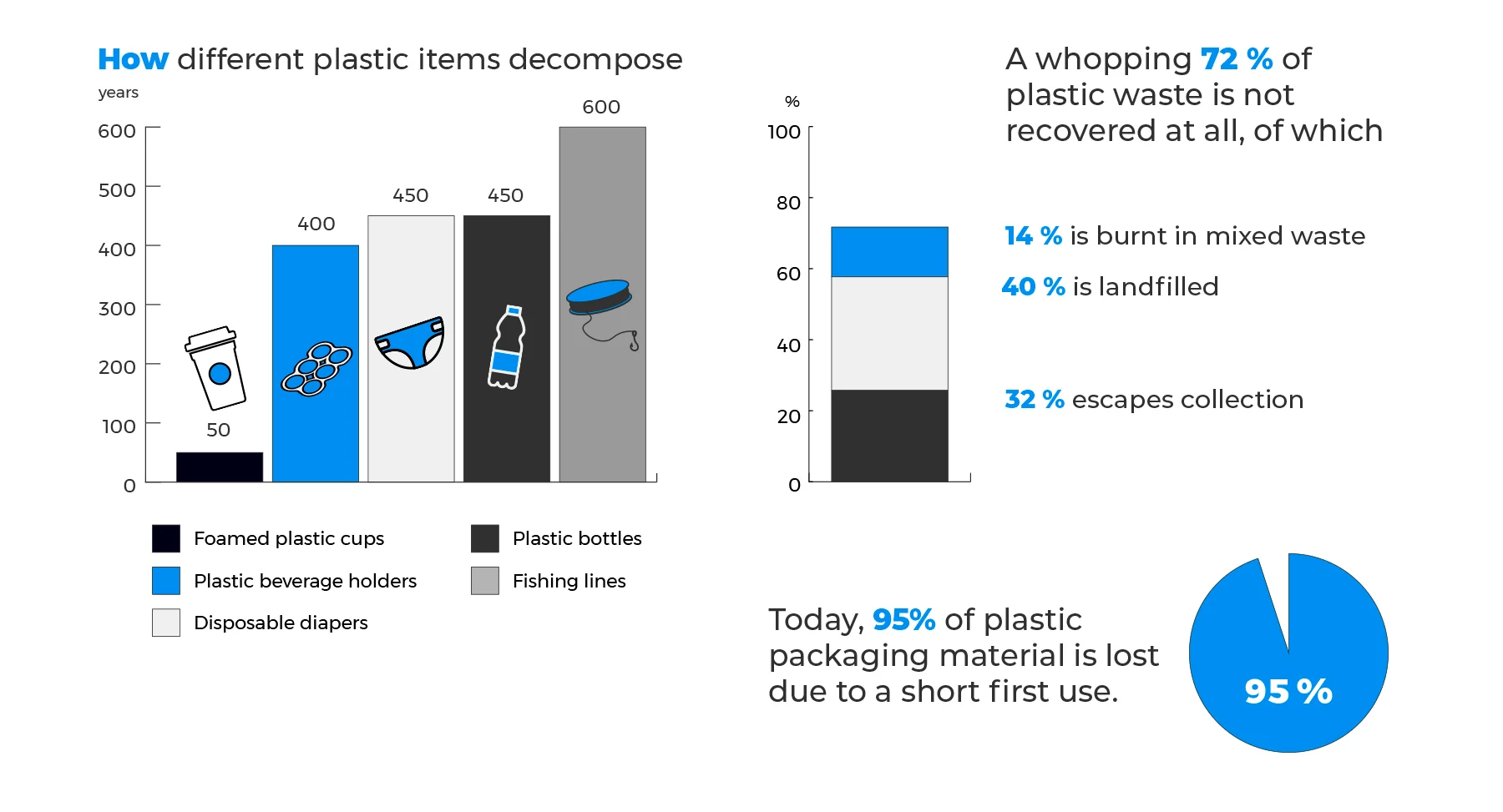

The use of plastic as a totally disposable material and its poor management by industries and governments has resulted in an environmental disaster. Due to waste mismanagement, a whopping one-third of plastic waste is estimated to have entered nature as pollution.

Since plastics are made from fossil fuels, burning plastic is poor use of our scarce natural resources. Plastic production is responsible of 4% of the world’s annual oil and gas demand. Carbon dioxide emissions grow each year from the increased production and incineration of waste plastic. Only 14% of plastic packaging is collected for recycling. Literally, what a waste!

Until now, recycling has been unprofitable, and the scalability of recycling methods has not been successful. Operating costs for recycling ventures have been high due to waste collection and separation costs and a limited supply of recyclable plastic. The enormous variety of plastic packaging has turned out to be a big headache for the recycling industry.

The scaling of recycling is a real possibility and could be done through solving quality issues stemming from high levels of mixed and contaminated plastic waste. An effective after-use plastics economy could help capture more material value and increase resource productivity. Thankfully, some forerunners such as Adidas have already taken their first steps towards re-using plastics in their products and are paving the way for smaller businesses as well.

Solving plastic pollution with NIR spectroscopy

The separation and sorting of plastic resins from Municipal Solid Waste facilities are a big step towards the circular economy of plastic. The wide range of plastic resins poses a unique challenge for the recycling process. Identification and sorting have traditionally been manual. This has made it slow, ineffective and costly even with labelling systems and the help of optical sorting methods such as hyperspectral cameras, which are also expensive.

Accurate sorting is crucial for producing high-quality recycled material. NIR spectroscopy is a great option for automated sorting as it offers specificity without any surface pre-treatment. During the identification, light from an incandescent bulb is reflected on the material. A certain type of plastic can be identified by the diffuse reflectance of the light back to a receiver, which is sensitive to the near-infrared part of the spectrum. Different types of plastics are then distinguished by their unique reflectance curve “fingerprint”, by using state-of-the-art machine learning algorithms. This makes the technique ideal for sorting unknown plastic waste with high accuracy, regardless of their color. (Black plastics still pose a challenge due to their poor reflectance of infra-red light, but many researchers are trying to overcome this limitation.)

The benefits of NIR sensors in recycling

Miniaturized and affordable NIR sensors and scanners can be incorporated into smart collection bins to identify plastics and help sort them more accurately. This can be done already at collection points which improves the rest of the recycling process. Hand-held scanners are also a useful tool for speeding up and improving the quality of manual sorting where needed. Perhaps in the future a handheld material scanner could help sort the plastics at home before they get thrown in the recycling bins.

NIR sensors have already been proved to be efficient in mechanical sorting of plastics in sorting facilities and rapid and accurate in in-line plastics detection. They are also an affordable option, as the development of MEMS technology has resulted in very cost-effective NIR solutions. For example, our NIRONE Sensors can be applied into industrial sorting machines, where the sensors identify and separate plastics in various steps of the material flow and sort them by type.

By Matti Tossavainen, Sales & Marketing Manager at Spectral Engines

#spectralengines #NIR #plastic #sorting